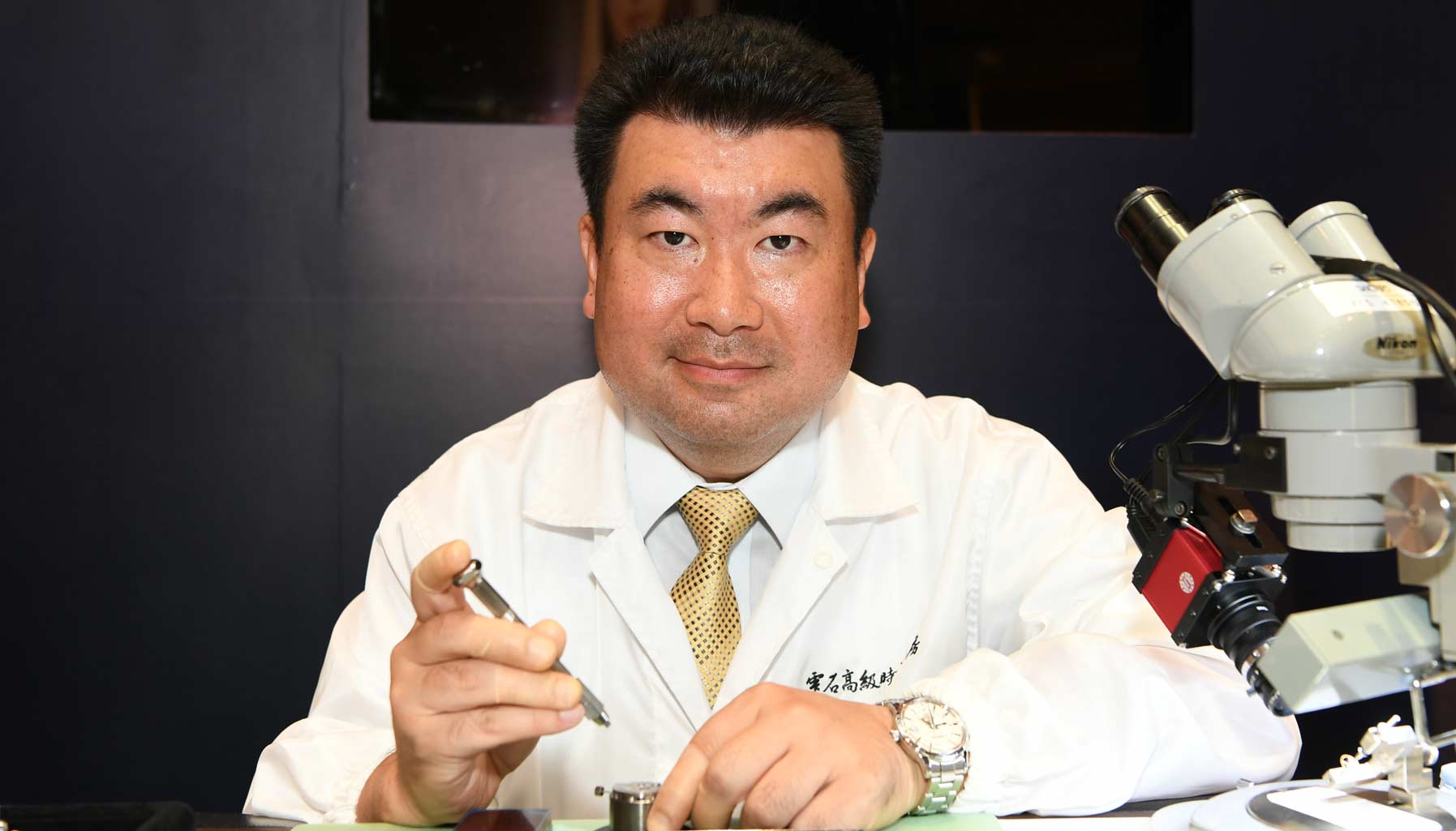

The Grandmaster

Watching Satoshi Hiraga’s precise, methodical technique as he assembled the new Grand Seiko Hi-Beat 36000 mechanical movement was an insight into the intricacies of watchmaking. The master craftsman moved with a steady, efficient grace, putting together the miniscule gears with seemingly no effort. Small wonder, as the Japanese artisan is at the very top of his game – he was officially recognised by the Japanese government as a Contemporary Master Craftsman in 2015.

The company’s steadfast emphasis on traditional craftsmanship in the watch-making process sets the brand apart from the Swiss brands that dominate the market. Hiraga explains, “I think the difference is that (the Swiss have) the tendency towards automatic assembly. In Japan, it is mainly done by hand.” The advantage, he feels, is the human touch – the ability to sense where each gear fits, where each part matches.

Hiraga puts his heart and mind into every watch he assembles, with an instinct he has honed over 27 years in the industry. That is also what he believes is one of the main reasons for Seiko’s long track record of excellence.

Watchmaking is a complicated process; there are aspects where, even with his wealth of experience, Hiraga finds challenging. To him, the most difficult aspect of making a Grand Seiko lies in the adjustment of the most important and most sensitive component of the watch – the hairspring, or balance spring. It requires not only steady hands but utmost focus to twist the spring with tweezers while delicately maintaining its balance, which can be undone with the slightest slip.

And even with his years of international praise from around the world Hiraga remains humble. The source of greatest pride, he says, is when the completed timepiece reaches “the accuracy at (my) expected level, reaches the customer and provides them satisfaction and happiness”.