From precious material selections to a final polish, eyewear from the British label is truly one-of-a-kind

When Sheel Davison-Lungley graduated from optometry school, she applied for a job at E. B. Meyrowitz but was beaten to the post by a classmate. “I’d always wanted to work there,” she recalls. “Everybody in optics knew about E. B. Meyrowitz.” So when Britain’s most discerning spectacles maker was put up for sale a little over a decade later, she snapped it up in 1993.

Established in 1875 by Emil Bruno Meyrowitz in what was then Prussia, the business built an enduring reputation not just for its handsome glasses but also for the founder’s meticulous approach to vision testing and “performance eyewear.” Meyrowitz kitted out every winning Le Mans team until 1950 and both Amelia Earhart and Charles Lindbergh with handmade goggles.

Under the stewardship of Davison-Lungley and her son, Jamie, Meyrowitz has remained a much-loved destination, run from a wonderfully quaint boutique on London’s Royal Arcade in Mayfair, which is now the company’s sole store. (E. B. Meyrowitz shops in New York and Paris are not affiliated with the brand.) Modern Meyrowitz’s reputation for quality remains second to none, as does the service the Davison-Lungleys offer. Jamie, the brand director, personally handles measurements for US clients during frequent trunk shows in eight major American cities.

“Today is a continuation of what the house was, but I think our attitudes towards design, craftsmanship and service make us very special in the modern world,” Sheel says. “Good service, design and getting into the nitty-gritty of one’s eyesight is very, very important to me.”

A single pair of eyeglasses from Meyrowitz’s Bespoke Collection, which tailors existing designs to a customer’s facial dimensions and offers a wide range of precious materials, can take many weeks to fabricate and require between two and three days of handwork at the brand’s workshop in Hampton Court, southwest of London. The frames start at about US$1,825 in acetate, or US$3,320 in horn. Ready-to-wear models are also available at US$660. Making a custom pair is a delightfully traditional process, and one that sets E.B.M. head and shoulders above mass-produced eyewear brands.

A material world

A pair of Bespoke Collection spectacles begins life as an eight-millimetre-thick block of raw material, chosen in consultation with the client. Meyrowitz can work with any number of precious materials, including cellulose acetate, sustainably sourced buffalo horn, antique tortoise shell and even valuable hardwoods such as maple and walnut.

In the thin of It

The block of selected material (in this case, buffalo horn) then needs sanding down to the client’s desired thickness. Typically, Meyrowitz frames measure less than half a centimetre at their thickest, so a miniature drum sander is used to thin the material millimetre by millimetre.

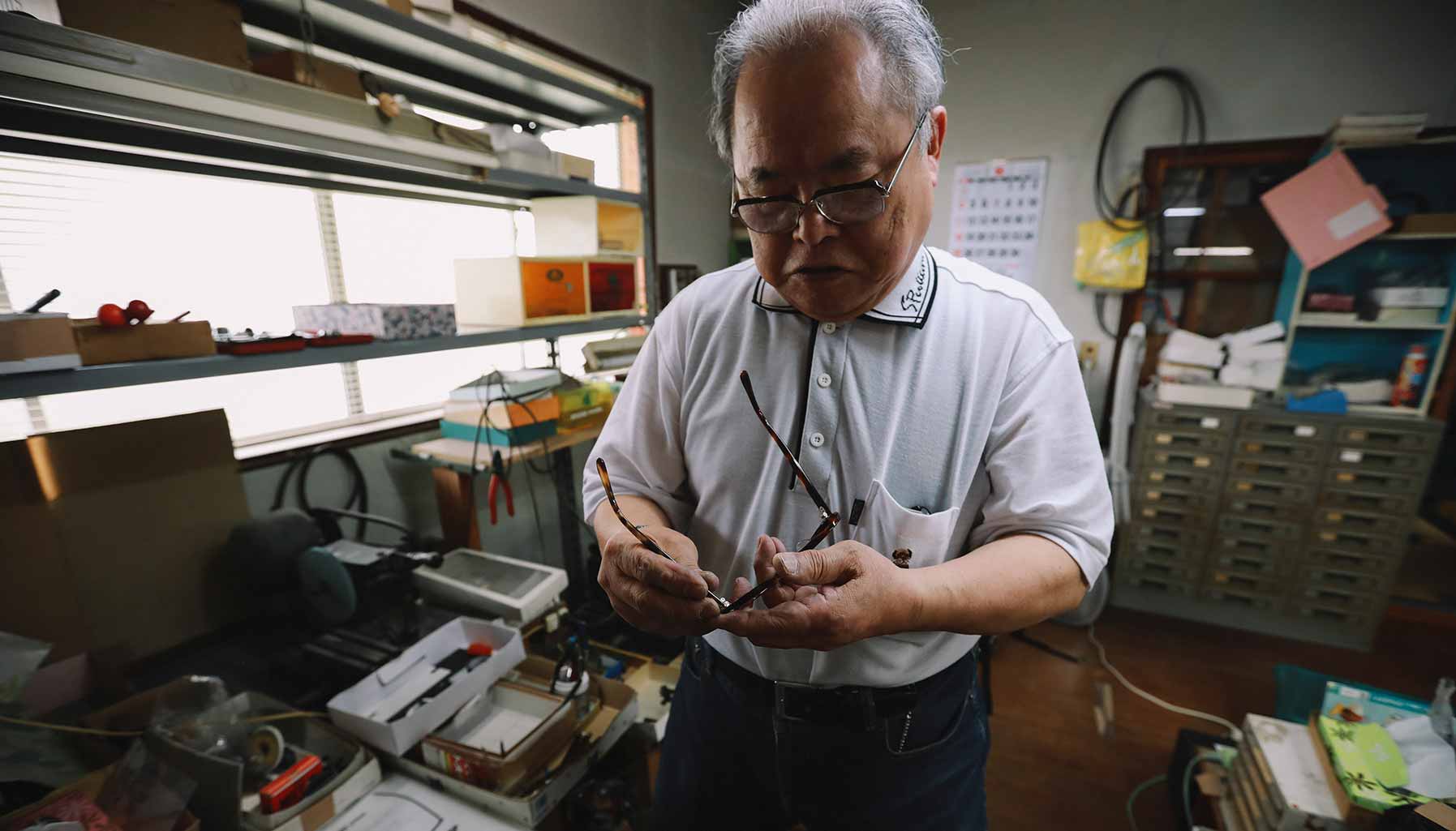

Lasting impressions

The Meyrowitz team will take up to 23 measurements for a pair of glasses, then draft a design by hand and convert it into a digital file. A machine printer in the workshop reads this file and prints a white outline of the glasses onto the freshly thinned block of material for the craftsmen to follow.

Making the cut

At this point, the frames are cut out by hand, tracing the printer’s white lines and using both handsaws and files to painstakingly shape the glasses. “It needs the sensitivity of the human touch,” Jamie says. “A machine cutter would be too aggressive and risk breaking the material.”

Slow and steady

Once the spectacles’ approximate shape has been cut, a small sanding wheel, about the diameter of a No. 2 pencil, hones the edges of the rims and fine-tunes their shape. Here, too, delicacy is everything: The frames are guided around the sander by hand, with the craftsman’s fingers just a whisper away from the whirring wheel.

Close shaves

Now it’s back to the workbench to contour the frames using a scalpel. Most custom glasses will have a relatively thick bridge and slimmer, tapered rims and arms for lightness and comfort. Meyrowitz’s team achieves this effect through yet more handwork, gently shaving the acetate or horn, followed by a final round of sanding, using an extremely fine sandpaper to smooth every surface.

In the groove

With the frames shaped, tiny holes for the hinges that attach the arms are drilled, and a fine groove is bored into the inside of the rims to secure the glass lenses. This stage is one of the most delicate of the entire process—if the craftsman is too vigorous, he risks cracking the finely shaped rims. “If you make just one mistake, most of the time you can’t do anything to fix it,” Jamie says. “You have to just make it again.”

Jet set

The most comfortable glasses are shaped to the contours of the wearer’s face, and Meyrowitz’s are no exception. To ensure the perfect degree of curvature, a convex mold is selected based on a client’s measurements and the frames are strapped to it and heated with a jet of hot air, which permanently sets the frames in a subtle concave shape to wrap around the client’s eyes.

Spick and span

The finished frames are then delicately polished, guided by hand on two different polishing wheels. “It’s a process that really brings them to life,” says Sheel. It can take several hours and multiple rounds of buffing to bring out the natural sheen of fine horn or tortoiseshell.

Through the looking glass

Finally, with the frames perfected and quality-checked, the lenses—made by an external manufacturer to Meyrowitz’s specifications—are inserted, and the arms’ metal hinges are carefully affixed. With that, your bespoke spectacles are complete and ready to be either shipped or fitted in-store.

This story was first published on Robb Report USA