Lab Series

Patek Philippe is one of the few remaining bastions of traditional watchmaking, but one would be remiss to think of Patek Philippe as a firm that’s got its head stuck in the 1800s. Not only has the company continually stayed abreast of technology, it leads the industry in seeking out the most cutting-edge materials and production techniques.

Since 2005, Patek Philippe has embarked on what it termed the Advanced Research project. This marked its first official foray into the most promising futuristic technology for watchmaking: silicon. Offering a host of benefits including to-the-micron fabrication precision, amagnetism and hitherto unprecedented hardness, silicon allowed Patek Philippe to make an escapement wheel that required no lubrication. It was called the Silinvar escape wheel and it debuted in the Annual Calendar Ref 5250.

In 2006, Patek Philippe launched a balance spring also made of Silinvar. Named the Spiromax balance spring, it brought all of the known advantages of silicon into the heart of the watch, yielding higher timekeeping precision and lower propensity for wear and tear. What gives the Spiromax its faculty for superior chronometric performance is a short length of the spring on the outermost part that’s slightly thickened. The Annual Calendar Ref 5350 was the first watch to be made with a Spiromax balance spring.

Next, in 2008, was the Pulsomax escapement, which included the Silinvar escape wheel, Spiromax balance spring and a silicon lever. Used in the Annual Calendar Ref 5450, the latter was made without pallet stones because of the friction-free properties of silicon.

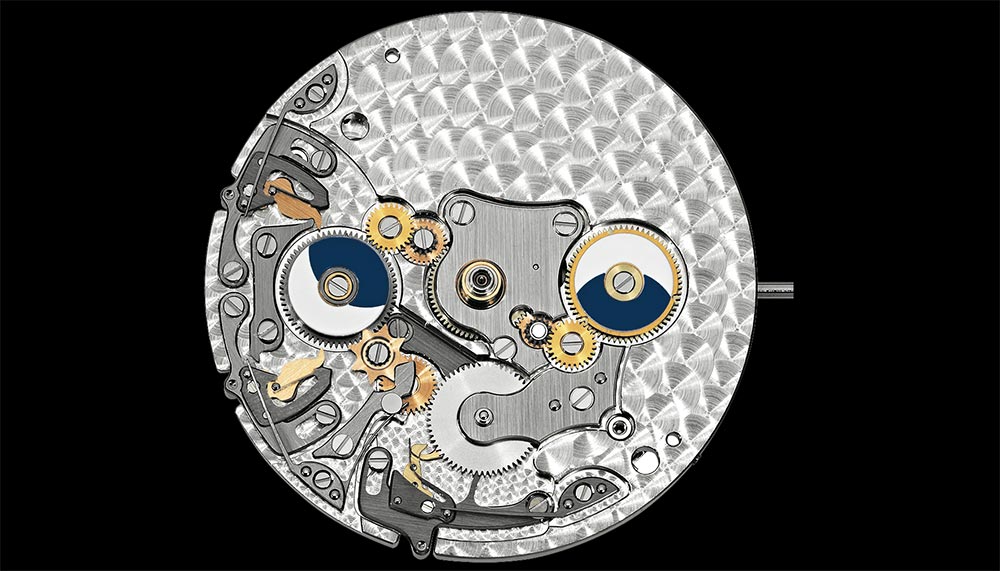

Then, in 2011, the entire regulating organ of the movement was made in silicon. With the introduction of a silicon balance wheel named GyromaxSi, the system was called Oscillomax. GyromaxSi sports a wholly different geometry than conventional balance wheels and proffers extreme lightness at the centre but maximum weight distribution to the outermost edges thanks to adjustable gold weights. The Perpetual Calendar Ref 5550 was the first watch made with the Oscillomax system.

Six years after Ref 5550, Patek Philippe unveiled the next chapter of this riveting series.

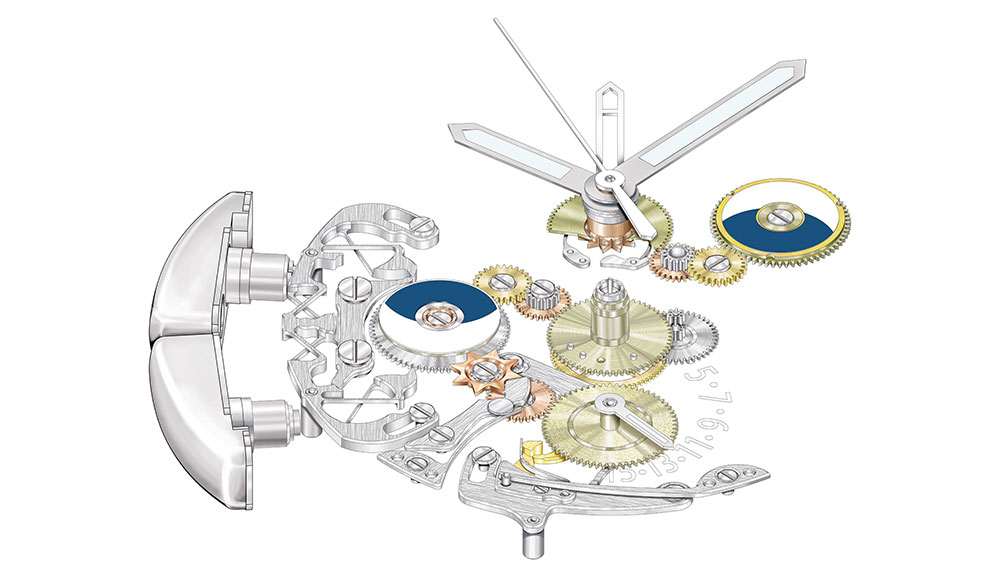

The Aquanaut Travel Time Ref 5650 takes the Advanced Research project down a different path. Its main technical achievement is what Patek Philippe has called the compliant mechanism, a single component device that allows the GMT function to be adjusted forwards and backwards.

The most amazing thing about the compliant mechanism is that it allows the manufacture to greatly reduce the overall number of components needed for the GMT function. A conventional GMT device requires about 37 individual parts while in Ref 5650 there are just 12. It operates on the principle of leaf springs, which are the thin filigreed criss-crossing parts of the mechanism. Pushing the buttons causes the springs to flex and releasing them brings the springs back to their original position.

Ref 5650 also comes with an improved Spiromax balance spring with a thickened region not just on the outermost part but also near its core. This has the effect of increasing the rate stability of the watch to -1/+2 seconds per day (earlier Spiromax springs have a -3/+2 maximum daily rate deviation).

Patek Philippe’s Advanced Research project started out as an expansion of its R&D on silicon in watchmaking, but with Ref 5650 it has gone beyond that. Advanced Research offers a glimpse into the most brilliant minds of the manufacture and hints at the direction in which the company – and watchmaking at large – is heading.